- Request A Quote

- 1-800-668-3979

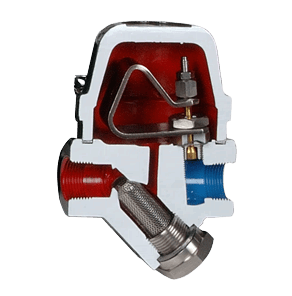

M3A/GM3 Steam Trap

A series of steam traps designed for fast start-up and modulating discharge with no live steam loss on service up to 30 psig differential. Ideal where a forged body with "Y" type strainer is required to handle light condensate loads including low pressure driplegs. The single blade element offers long-term, trouble-free service because it's not prone to dirt build-up as encountered with many other bimetal designs.

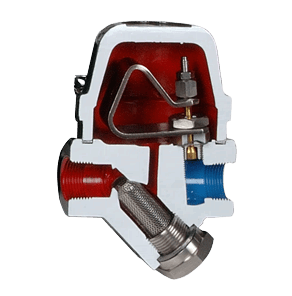

M6A/GM6 Steam Trap

A series of steam traps designed for low condensate capacity needs, yet incorporate a forged carbon steel body and "Y" type strainer. The M6A/GM6 utilizes thermostatic and thermodynamic forces for steam-tight shutoff for greater energy efficiency and extended seat life, with no live steam loss. The single blade element - offers long-term, trouble-free service because it's not prone to dirt build-up as encountered with many other bimetal designs. Maximum operating: 70 psig / 4,8 bar

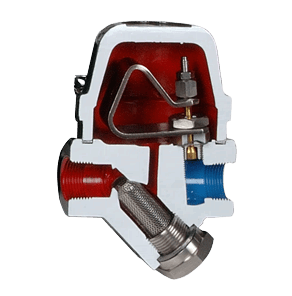

DM6/DM12 Steam Trap

A line of lightweight, yet rugged, steam traps that provide modulating discharge of light condensate loads without the loss of live steam. These fully maintainable steam traps feature energy-efficient operation with excellent start-up capacities for services with operating pressures up to 150 psi. Maximum Operating Pressure – DM6: 70 psi (4,8 bar); DM12: 150 psi (10,3 bar)

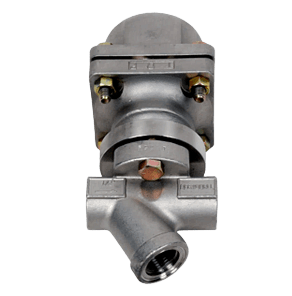

DM10E Steam Trap

Commonly used as an automatic drain for freeze-proof protection of condensate return systems and manifolds and on tracer systems where maximum use of BTU's from condensate is desired. Single blade element offers long-term, trouble-free service because it's not prone to dirt build-up as encountered with many other bimetal designs.

M10/GM10 Steam Trap

Designed to handle varying loads of process applications and provide fast start-up and modulating discharge with no live steam loss on services up to 120 psi (8,3 bar) operating pressure. The single blad element offers long-term, trouble-free service because it's not prone to dirt build-up as encountered with many other bimetal designs. Maximum operating pressure: 120 psig / 8,3 bar

DS12 Steam Trap

A lightweight steam trap for plant applications requiring sealed Stainless Steel construction for tracing services with operating pressures up to 150 pisg. Single blade element offers long-term, trouble-free service because it's not prone to build-up as encountered with many other bimetal designs.

M16/GM16 Steam Trap

A series of steam traps designed to handle the varying loads on process applications and provide fast start-up and modulating service with no live steam loss. The single blade element offers long-term, trouble-free service because it's not prone to dirt build-up as encountered with many other bimetal designs. Maximum operating pressure: 200 psig / 13,8 bar

M22 / TM22 Steam Trap

Developed to make use of the latent heat of steam and the sensible heat of condensate prior to discharge. For tracing services with differential pressures up to 300 psi (20,7 bar), these traps are completely maintainable.

TS22 Steam Trap

For services with operating pressures up to 300 psig (20,7 bar), this model is designed to efficiently make use of the sensible heat by retaining condensate within the tracer line.

M25/GM25 Steam Trap

A series of compact, high capacity steam traps developed to handle the varying loads and pressures typical of process and heating applications with operating pressures to 320 psi (22,1 bar). The single blade element offers long-term, trouble-free service because it's not prone to dirt build-up as encountered with many other bimetal designs.

DM25 Steam Trap

For use on a steam main dripleg and critical tracing service with operating pressures up to 320 psig (22,1 bar). The single blade element offers long-term, trouble-free service because it's not prone to dirt build-up as encountered with many other bimetal designs.

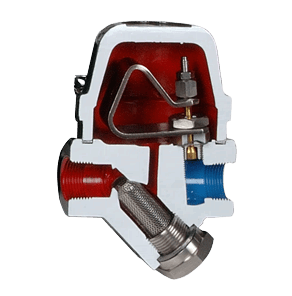

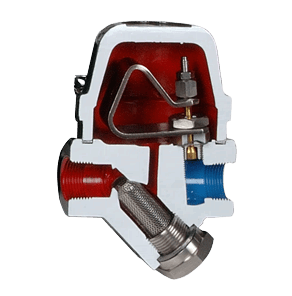

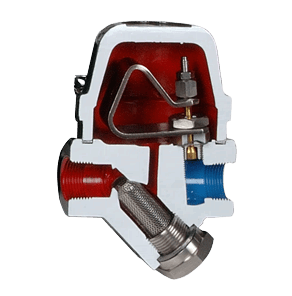

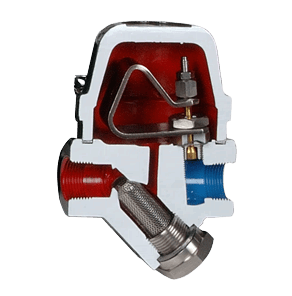

M40/M64/M100 Steam Trap

A series of heavy duty steam traps in 1-1/2" and 2" sizes designed specifically for high pressure, high flow process applications. Featuring built-in "Y" type strainers and check valves, this series can be used for services with operating pressures up to 900 psi (62 bar). The single blade element offers long-term, trouble-free service because it's not prone to dirt build-up as encountered with many other bimetal designs.

DM40/64/100/100F/160/320 Steam Trap

An excellent choice for high pressure applications, these rugged steam traps provide fast start-up and high performance on steam main driplegs and pressure process applications with operating pressure ranges from 250 psi (17,2 bar) to 2000 psi (137,9 bar). The single blade element offers long-term, trouble-free service because it’s not prone to dirt build-up as encountered with many other bimetal designs

Magnum Steam Trap

A versatile line of high capacity steam traps, Bestobell's Magnum can be supplied with up to 18 bimetallic elements for hot condensate flows as high as 149,000 pounds per hour. With five models available for operating pressures up to 320 psig, you can add or delete elements to match your changing conditions. Different Models to handle operating pressures from: 30 psi (2,1 bar) to 320 psi (22,1 bar)

Universal Delta Element Steam Trap

Bestobell Steam offers a universal mount, bimetallic steam trap for plant applications requiring standardized connections. The universal mounting connections allow trap use on an manufacturer's universal mount. The two bolt replacement module is easy to install, replace or rebuild.