- Request A Quote

- 1-800-668-3979

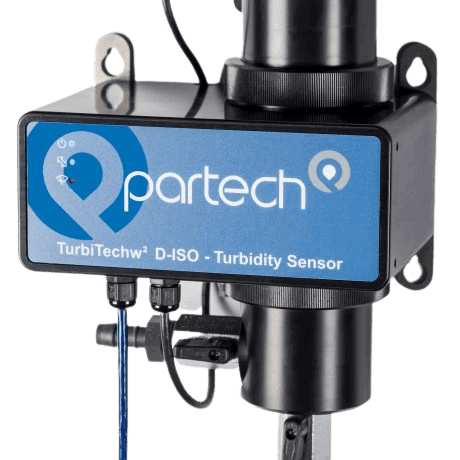

TurbiTechw² D-ISO Turbidity Sensor

The TurbiTechw² D-ISO Sensor has been specifically designed to monitor final treated, potable and filter water. The sensor is extremely sensitive and is capable of discriminating changes in Turbidity of less than 0.01NTU and is ISO7027 compliant. The 90º light scatter monitoring technique makes the sensor sensitive to a wide range of particle sizes, Accuracy ± 2% of reading or 0.02 NTU whichever is greater for range 0- 30 NTU and ±0.1 NTU whichever is greater for range of 0-200 NTU.

Partech TurbiTechw² LS - Suspended Solids or Turbidity

The TurbiTechw² LS Sensor is designed to monitor the levels of suspended solids or turbidity typically found in final effluent from municipal and industrial wastewater treatment plants. It is also great at monitoring solids in the intake to both effluent and drinking water treatment processes. Available Ranges: 0 - 100 NTU, 0 - 500 NTU, 0 -1000 NTU. Monitoring of these key parameters requires sensors that are reliable and accurate, the TurbiTechw² LS meets this requirement perfectly. The large optical surfaces and sample volume ensure that the information provided by the sensor is both representative of the process and tolerant of fouling. In addition, the sensor incorporates a self cleaning mechanism that ensures that the optical surfaces are kept clean at all times, the cleaning system is designed to avoid problems with ragging and does not smear the optical system.

TurbiTechw² LA Suspended Solids Sensor

Self Cleaning Suspended Solids Sensor. Range 0 - 20,000 mg/l The TurbiTechw² LA Sensor has been designed for use in aeration systems monitoring suspended solids also known as mixed liquor suspended solids or activated sludge where solids are typically in the range of 1,500 to 3,500 mg/l. The sensor can also measure Returned Activated Sludge (RAS), Surplus Activated Sludge (SAS) and suspended solids or turbidity. The fully automatic self cleaning system ensures that manual intervention on a routine basis is not required.

TurbiTechw² HR - Self cleaning Suspended Solids Sensor

Range 0 - 50,000 mg/l. The TurbiTechw² HR Sensor has been specifically designed for use in wastewater treatment systems where high levels of suspended solids are desirable in the aeration phase. Membrane Bio Reactors (MBR) typically run with MLSS values in the region of 8,000 to 14,000 mg/l. High MLSS concentrations promote numerous process benefits, including stable operation, complete nitrification, and reduced biosolids production reducing biological volume requirements (and associated footprint) to only 20-30 percent of conventional biological processes.

7300w² Monitor (Analytical Transmitter)

The 7300w² Monitor is the core product in the WaterWatch² range. The monitor is designed to interface with all of the sensors in the WaterWatch² range. The monitor specification provides all the connections required for 1 or 2 sensors, systems can be created by the use of expansion boxes to include multiple sensors. The maximum number of sensors will be limited by the practicalities of most sites. We anticipate 8 being a sensible maximum although many more can be accommodated.

Mobrey MSM400 Ultrasonic Suspended Solids Monitoring System

The Mobrey MSM400 system continuously monitors the suspended solids or sludge density contained in, or flowing from, a clarifier or settlement tank during de-sludging. Many years of practical experience have shown that measurement of ultrasonic attenuation in a slurry is directly proportional to the percentage of suspended solids.The MSM400 system uses this principle to produce a digital display of the suspended solids measurement.

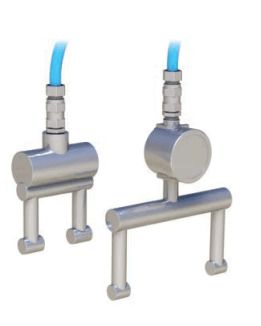

Delta-Mobrey MCU200 Suspended solids Level Controller & Sensors

The MCU controller and gap sensor when used together provide an ultrasonic point level liquid switch. Typical applications include sludge blanket level detection in settlement tanks, interface detection for immiscible liquids and contamination detection, such as oil in water or water in oil. The MCU201 and MCU203 control units provide simple and economical control electronics for wall-mounting near a tank or pipeline containing a single ultrasonic gap sensor. The sensors operate on the attenuation of an ultrasonic signal through the fluid.

Delta-Mobrey Ultrasonic Sludge density sensors for alumina production

The Mobrey ultrasonic gap sensor is used for measuring clarity and interface levels in Red Mud decanters that are used in the production of aluminium oxide from Bauxite.

In-Situ AquaTROLL Multiparameter Sensor

The In-Situ AquaTROLL is a cost effective multiprobe that integrates with plant control systems for long term installation using a local controller, direct connection or wireless telemetry. With interchangeable sensors, the probe replaces multiple instruments, reducing overall monitoring costs. PARAMETERS • Dissolved Oxygen (RDO) • Turbidity • Total Suspended Solids • Temperature/Conductivity • Pressure • Level • Salinity • pH/ORP • Nitrate (NO3-) • Rhodamine WT Fluorescence Intensity • Ammonium (NH4+) • Chloride (Cl-) • Blue Green Algae-Phycocerythrin

Partech model 750w² Monitor Portable Water Quality Meter

The 750w² handheld water quality monitor is a simple robust and accurate tool for measuring a full set of water quality parameters with a single unit. The monitor’s simple to use interface, multiple sensor opitions and a field ready design makes the 750w² the market leader for on site monitoring of TSS, Turbidity, Sludge Level, pH, Redox and dissolved oxygen.

Partech SludgeWatch 715 Sludge Blanket Detector

The SludgeWatch 715 provides a simple, low cost method of spot checking the sludge blanket level in a wide variety of settlement tanks. The cable reel design removes the need for any additional carrying bag. The sludge blanket is detected by winding the sensor down into the tank, the audible tone will change and the LED illuminates once the sensor has reached the blanket. This method of sludge blanket detection offer major improvements over traditional SludgeJudge type systems in terms of both repeatability and importantly health and safety – no more manhandling 4 metre tubes full of contaminated wastewater.

Partech IR ’C’ Suspended Solids Sensors for Sludge blanket detection

The Partech IR ’C’ Suspended Solids Sensors along with the 7300w² Monitor provides a reliable method of detecting the sludge blanket level in clarifiers and settlement tanks, or increasing levels of suspended solids or sludge density in large range of processes. Partech’s range of infrared sensors can be used for measurement of suspended solids, sludge density, and turbidity in a wide range of applications, which includes Mixed Liquor and Final Effluent Suspended Solids and Sludge Blanket Detection.

Partech SoliTechw² - IR Suspended Solids Sensors - Portable Use

Partech’s range of SoliTechw² IR infrared sensors can be used for the measurement of suspended solids, sludge density, and turbidity in a wide range of applications, which includes Mixed Liquor (MLSS), Total Suspended Solids (TSS) and Sludge Blanket Detection