- Request A Quote

- 1-800-668-3979

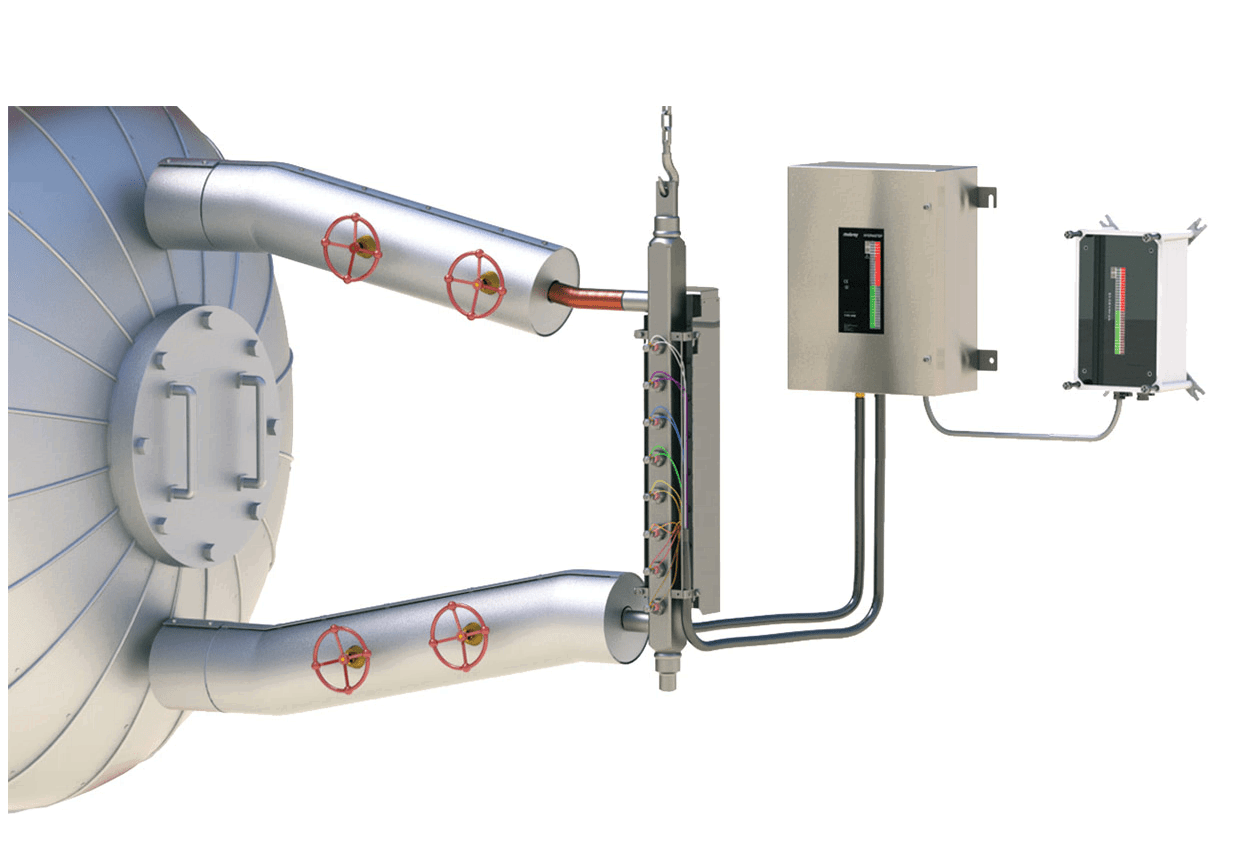

Hydrastep Steam Drum Water Level Monitoring

Failure to detect low water levels in steam raising plant can have costly and potentially disastrous consequences. Fail-safe water level detection is vital to prevent damage to plants and personnel. Trusted globally for 50 years, the Hydrastep electronic gauging system is the ideal ‘fit and forget’ solution to overcome the problems associated with unreliable and maintenance-intensive gauge glasses. INDEPENDENTLY VALIDATED: An independent report by Factory Mutual Research concluded that the statistical probability of Hydrastep missing a trip condition is less than 1 in 300 million and that nuisance trips will be less than 1 in 10 million.

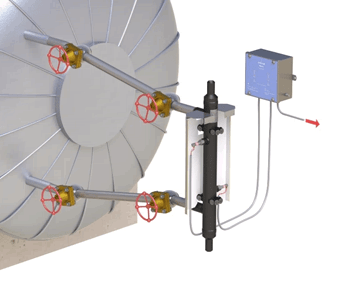

Delta-Mobrey Hydratect 2462 Steam and Water Detection System

Hydratect can be used in a wide variety of situations wherever the detection of water or steam is vital for safe and efficient plant operation. A typical application to ensure TWIP (Turbine Water Induction Protection) is condensate level detection in drain pots (condensate pots). Hydratect can be used to give compliance with ASME TDP-1, Prevention of Water Damage to Steam Turbines Used for Electric Power Generation: Fossil-Fueled Plants.