- Request A Quote

- 1-800-668-3979

Pro-V™ M22 Multivariable Flowmeter (Inline)

VorTek Instruments’ Pro-V™ multivariable flowmeters utilize three primary sensing elements–a vortex shedding velocity sensor, an RTD temperature sensor, and a solid-state pressure transducer–to measure the mass flow rate of gases, liquids and steam.

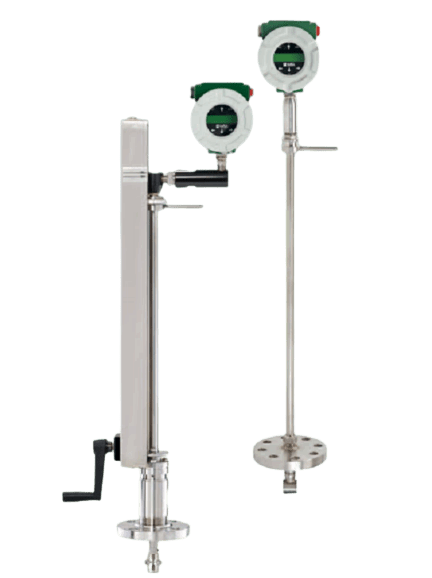

PIT - Insertion Magnetic Flow Meter with Optional Extraction Device

The PIT Probe-Type Insertion Magnetic Flow Meter is designed to measure the flow velocity of conductive liquids in large diameter pipes. The insertion-style design makes it cost-effective for larger lines in comparison to large inline magnetic flow meters from the aspect of purchase price as well as installation cost. This is because the insertion-probe design requires just a single bore hole in the side of the pipe instead of requiring an entire pipe section to be removed and reconfigured like inline magnetic flow meters. Insertion magnetic flow meters also require sigificantly less material for construction and are not as costly to ship as they are smaller than large inline flow bodies, leading to cost savings.

Vortek Pro-V™ Multivariable Flowmeter Model M24 In-line Vortex

VorTek Instruments’ Pro-V™ multivariable flowmeters utilize three primary sensing elements–a vortex shedding velocity sensor, an RTD temperature sensor, and a solid-state pressure transducer–to measure the mass flow rate of gases, liquids and steam. The M24 is available in a reducing configuration which allows the meter to be reduced internally from the nominal line size thus increasing the units useable measuring range. The M24 has added the ability to power the meter with the POE, Power over Ethernet, functionality with a POE switch or router

VorCone™ - Steam Quality / Two Phase Flow Meters

VorTek Instruments’ VorCone™ flow meters utilize two different flow meter technologies in combination; vortex and differential pressure. This combination allows for the prediction of the fluid density, volumetric flow rate and mass flow rate without any fluid density information being required from an external source. In saturated steam service, the meter produces a reliable steam quality (dryness) measurement and steam mass flow rate reading.

Pro-V™ M23 Multivariable Flowmeter (Insertion)

Insertion vortex meters measure flow by detecting the local velocity at a strategically located position within the pipe. Our Pro-V™ Model M23 detects the frequency at which vortices are shed from the bluff body located within the sensor head and then converts this to a volumetric flow in the electronics. The Pro-V™ Model M23 also uses the local velocity, along with other parameters, such as fluid type, pipe size and Reynolds number to calculate the average pipe velocity, and consequently, the volumetric flow rate.